Did you know that only 3% of the water on earth is fresh? As the population grows, it is more important than ever to save water and reuse existing water through sewage treatment plants. Depending on the source of the sewage, many chemicals (such as phosphates) are mixed into it, which makes the water not directly usable for drinking and cleaning. At this point, the water treatment equipment should use chemical dosing to remove these chemicals.

What is chemical dosing?

Chemical dosing is the process of treating wastewater with chemicals such as iron, aluminum and even some salts to remove the high levels of chemicals present in it. This chemical dosing is done in controlled amounts to remove unwanted elements from the wastewater and make them usable again. Chemical dosing is an integral part of the water treatment process.

How does it work?

In the first step, operators of industrial wastewater treatment systems identify the chemicals dissolved in the water and create a report based on their findings. This report helps the wastewater treatment plant operator determine the correct chemicals to dose to make the water drinkable again. These operators must be constantly aware of what is happening in the treatment plant and adjust dosing levels and rates accordingly. For example, if there is a high level of phosphate in the wastewater, more iron is added to counteract the effects of phosphate. Overall, they know the levels of chemicals present in the wastewater and chemically meter accordingly.

Since this manual check is not always feasible, many companies have developed an automated system that automatically checks the chemical levels in the inlet stream, analyzes the content, sends this data in real time to the chemical metering system, and then automatically adjusts the speed and volume of the metering pumps located at the chemical feed station. The entire process is monitored by an operator to increase efficiency.

How to do chemical dosing?

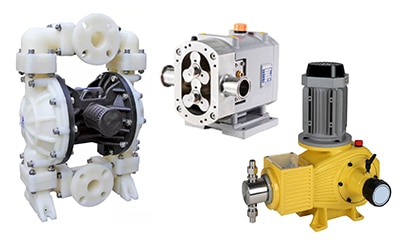

In many water treatment scenarios, such as water plants, power plants, chemical plants, petrochemicals, etc., chemical dosing pumps are commonly used for the direct dosing of chemicals. The dosing pump can measure the conveyed liquid (especially corrosive liquid), can meet certain accuracy requirements, and the flow rate can be steplessly adjusted in the range of 0-100%. The functions of conveying, metering and regulating are completed simultaneously, thus simplifying the production process.

What does the chemical dosing system look like?

Chemical dosing system will depend on many things, such as location, space availability, nature of the chemical, plant size, etc. Typically, there will be at least two chemical storage tanks used to store chemicals for maintenance purposes. The water from the inlet stream flows through a number of filters in the chemical feed system. Each filter reduces the debris in the chemical and the water flows to the metering point. This is where the chemicals in the tank are released into the water to treat and remove dissolved chemicals from the water. Depending on the level and amount of dissolved chemicals in the wastewater, these chemicals are released at a certain rate and pressure.

Finally, the water is measured through a calibration point and if it meets existing standards, the drinking water is sent for a final chemical purification and is then ready for use. If it contains any additional chemicals, the water is sent back again for chemical metering.

These chemical dosing systems are very efficient, which is what makes them an integral part of any wastewater treatment plant.