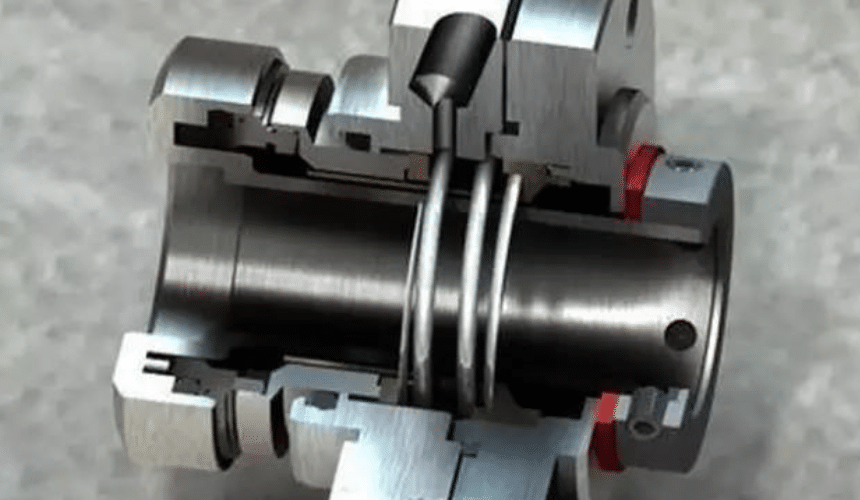

Mechanical seals are a key component in centrifugal pump systems. These devices maintain the integrity of the pump system by preventing fluid leakage and keeping contaminants out. Mechanical seal systems are used in a variety of seal designs to detect leaks, control the sealing environment, and lubricate secondary seals.

There are several mechanical seal types available depending on the pump type and process variant. Each seal variant has its own unique design and characteristics that make it suitable for a particular application.

This article highlights the advantages and disadvantages of the different types of mechanical seals used in centrifugal pumps.

Different types of mechanical seals for centrifugal pumps

Mechanical seal types vary in design, arrangement, and how they disperse the hydraulic pressure acting on their surfaces. The most common types of seals include

- Balanced seals

- Unbalanced seals

- Pusher seals

- Non-push seals

- Conventional Seals

- Collective Seals

Balanced and unbalanced seals

A balanced mechanical seal device is a system in which the forces acting on the seal faces are balanced. Due to the lower end loads, the seal faces are more evenly lubricated and the seal life is longer.

Balanced mechanical seals are particularly suitable for higher operating pressures, typically above 200 PSIG. They are also a good choice when handling low lubricity and highly volatile fluids.

Unbalanced mechanical seal types are often used as a more economical alternative to more complex balanced seals. Unbalanced seals may also exhibit less product leakage due to tighter control of the mask, but the result will exhibit a much lower mean time between failures. Unbalanced seals are not recommended for high pressure or most hydrocarbon applications.

Pusher and non-pusher seals

Pusher seals utilize one or more springs to maintain the seal closing force. The springs can be in the rotating or stationary element of a mechanical seal. Pushrod seals can provide a seal at very high pressures, but have a disadvantage because the elastomer beneath the main sealing surface is subject to wear as that surface moves along the shaft/sleeve during operation.

Non-push type seals use metal or elastomeric bellows to maintain the seal closing force. These seals are well suited for dirty and high temperature applications. Bellows seals are limited to medium/low pressure applications.

Both pusher and non-pusher designs are available in balanced and unbalanced configurations.

Conventional mechanical seals

Conventional seals are typically lower cost and are typically installed on general service equipment. These seals require a higher level of operator skill to perform maintenance as they are installed as separate components.

Packaged seals

Packaged mechanical seals integrate all sealing elements into one assembly. This greatly reduces the possibility of assembly errors and the time required to replace.

Key considerations when choosing different types of mechanical seals for pumps

When determining the type of seal system for a centrifugal pump, the operator needs to make a selection based on its unique application. Failure to select the correct seal type can result in loss of pump integrity, failure and costly repairs. To avoid these undesirable results, all operators must consider the following factors before making a decision.

The type of fluid to be pumped

The fluid you are pumping is one of the most important factors to consider when deciding on a seal type.

Factors such as cleanliness, lubricity and volatility can significantly affect the design of mechanical seals and seal support systems.

Pump Fluid Pressure

The amount of pressure applied to the mechanical seal face has a significant effect on its performance. If the pump is to be operated at low pressure, an unbalanced mechanical seal will be appropriate. However, under conditions where higher pressures are expected, a balanced seal will prove to be a more reliable solution.

Temperature Considerations

Balanced mechanical seals perform better than unbalanced mechanical seals under conditions where the operating temperature is higher than normal. Thermally sensitive components are better protected in balanced mechanical seals than in other seal types.

Operator Safety Issues

With all types of machinery, operator safety is of paramount importance. The use of double mechanical seals in centrifugal pumps provides additional protection because they increase sealing capacity and are generally more reliable.