Daily work rules for water treatment dosing staff

- Operation procedures for dosing personnel

(1) Dosing medicine accurately, on time and in quantity;

(2) When using intermittent sewage discharge, the medicine should be added after the sewage discharge;

(3) Each time before dispensing the medicine, the dispensing barrel must be rinsed clean before the medicine can be poured into the dispensing barrel, and the dispensing barrel must be rinsed 2~3 times after adding the medicine;

(4) If two kinds of bactericidal and algaecide are used, they should be added alternately, and the adding time interval should be evenly distributed;

(5) Do not add scale and corrosion inhibitors on the day when the bactericidal and algaecide is added;

(6) Detailed records of daily dosing and sewage replacement.

- Dosing method

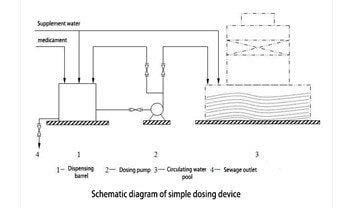

According to the current situation of the system and the characteristics of the medicament, the bactericidal and algaecide can be directly added to the sump. The method of adding the scale and corrosion inhibitor is as follows: a dispensing tank is arranged next to the circulating cooling water sump. The upper part of the dispensing tank is equipped with a water supply pipe and the lower part has a sewage outlet. After the medicine is added to the dispensing tank and diluted with supplemental water, it is continuously used with a metering pump. Evenly and gradually add to the collecting tank (as shown in the picture):

- Dosing position

Do not add the medicament to the water collection tank close to the drain, so as to avoid the medicament being directly discharged without entering the circulating water system; the medicament must have a mixing time in the pool to make it evenly mixed; do not add the medicament near the entrance of a certain pump, This will cause uneven distribution of drug concentration.

- Dosing method

(1) Adding method of scale and corrosion inhibitor: add the agent according to the amount to the washed dispensing barrel, add supplemental water under constant stirring to dilute the agent by about 3 to 5 times (the purpose of dilution is to balance the time of dosing , It can be undiluted according to needs), after stirring and mixing, turn on the dosing pump to adjust the dosing valve, so that the medicament is continuously and evenly added to the sump, and the addition is controlled within 20 to 24 hours.

(2) The method of adding the bactericidal and algae-killing agent: the impact intermittent dosing method is adopted for operation, and the agent is directly added to the collecting tank according to the amount, so that the circulating water maintains a considerable concentration of the agent for a period of time, so as to obtain the most effective killing And peeling effect.

- Matters needing attention

(1) Stack the water treatment chemicals neatly in the warehouse according to the grades to avoid confusion and misuse.

(2) According to the water quality test results (concentration factor, turbidity, total phosphorus), the circulating water control index and the dosing table should be compared, and the sewage, replacement or dosing operations should be carried out as required.

(3) Dosing personnel should wear protective equipment to avoid direct contact with skin and eyes. If the medicine comes into contact with the skin accidentally, rinse it off with plenty of water immediately.

(4) The method of adding water treatment chemicals must be strictly implemented in accordance with the relevant requirements, and safe production work must be done.

- Operation control of circulating cooling water operation

- According to the daily water quality analysis and test results, the necessary control of the amount of sewage, the amount of supplementary water and the amount of chemicals added to meet the required indicators.

- When the turbidity is greater than 20 mg/L, increase the discharge of sewage, increase the bypass flow rate, and replenish clean water until the turbidity of the circulating water is less than 20 mg/L.

- According to the current situation of the system, the concentration ratio should be increased as much as possible to save water and chemicals. If the concentration factor is greater than 4 times, the sewage volume is increased, clean water is added, and the concentration factor is less than 4 times.

- Total phosphorus control in circulating cooling water. According to the chemical performance of the scale and corrosion inhibitor, the total phosphorus in the circulating cooling water should be controlled within the range of 6-10mg/L.

(1) Due to the large amount of sewage discharged, the total phosphorus is low, so scale and corrosion inhibitors should be added appropriately to make the total phosphorus reach the required index, and the amount of sewage discharged should be adjusted.

(2) If the circulating water system discharges normally, but the total phosphorus is low, it is necessary to analyze and check whether the medicine is invalid or the deviation is too large. If the above reasons are eliminated, increase the dosage to make the total phosphorus meet the target requirements.

(3) If the total phosphorus in the circulating water is greater than 10mg/L, no scale and corrosion inhibitor will be added.

- When abnormal phenomena and problems in the operation of the circulating cooling water system and water treatment are found, it is necessary to report and deal with it to the relevant personnel in time, and make a record.

- Circulating cooling water index control range

| Project | unit | Control index | Analysis frequency | Analysis standard | |

| 1 | PH | mg/L | Natural balance | one time / day | |

| 2 | Ca2+ | mg/L | ≤200 | one time / day | GB/T15452-95 |

| 3 | Total iron | mg/L | <1 | one time / day | |

| 4 | Total phosphorus | mg/L | 6~10 | one time / day | |

| 5 | Alkalinity | mg/L | ≤500 | one time / day | GB/T15451-95 |

| 6 | Turbidity | mg/L | <20 | one time / day | GB/T13200-1991 |

| 7 | C1– | mg/L | ≤200 | one time / day | GB/T15453-95 |

| 8 | CODxa | mg/L | ≤10 | one time / day | GB/T15456-95 |

| 9 | Concentration factor | Times | 0.8~2 | one time / day |

Note: The concentration factor is approximately equal to the ratio of the mass concentration of Cl- in the circulating water to the supplemental water.

- In the circulating water for chemical addition treatment, the circulating water should be listed for testing to ensure the safety of the heat exchange equipment, and the acid and alkalinity of the circulating water should be strictly controlled to avoid corrosion to the equipment.

- We offer all kinds of metering dosing pump and water quality instrument.

HAOSH Metering pump products are as follows:

Apure Water quality instrument products are as follows:

pH /ORP: http://www.glenvironment.com/product/detail-112.html

EC /TDS: http://www.glenvironment.com/product/detail-113.html

DO: http://www.glenvironment.com/product/detail-114.html

CL: http://www.glenvironment.com/product/detail-135.html

TUR: http://www.glenvironment.com/product/detail-13.html

Digital Water Sensor: http://www.glenvironment.com/product/secondp-13.html