Pump is a mechanical device used to transfer different fluids from one position to another. It is a hydraulic device that lifts a fluid from a low to a high level and moves it from a low-pressure area to a high-pressure area. Pumps transfer fluids by converting the mechanical energy of the fluid into pressure energy (hydraulic energy).

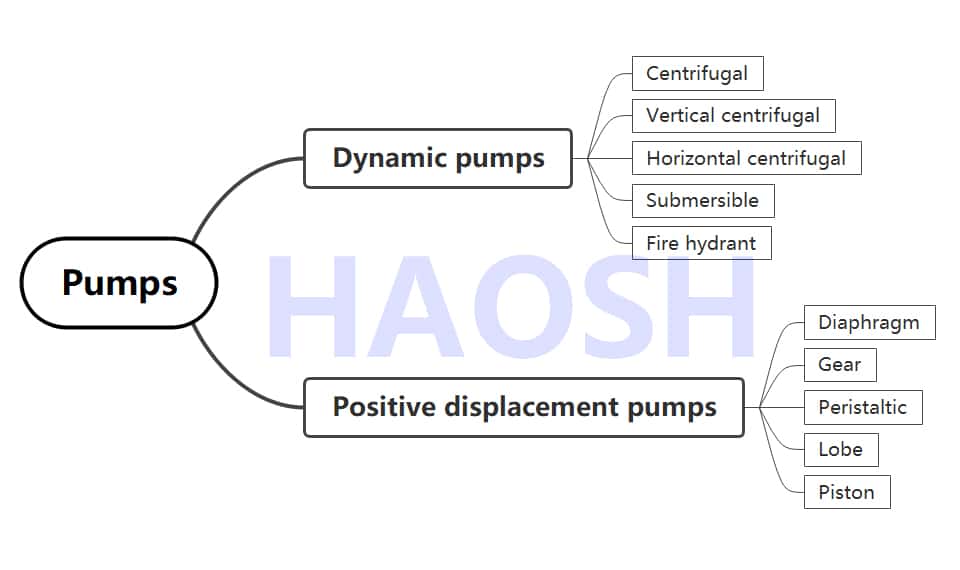

Classification of pumps

Pumps are divided into two main categories: dynamic and positive displacement (aka displacement)

The following are some of the pumps under these two categories:

Dynamic pumps:

- Centrifugal pumps

- Vertical centrifugal pumps

- Horizontal centrifugal pumps

- Submersible pumps

- Fire hydrant system

Positive displacement pumps:

- Diaphragm pumps

- Gear pumps

- Peristaltic pumps

- Cam pumps

- Piston pumps

Dynamic Pumps

There are different types of dynamic pumps, some of which will be discussed below, such as centrifugal pumps, vertical centrifugal pumps, horizontal centrifugal pumps, submersible pumps and fire hydrant systems.

Centrifugal Pumps

These types of pumps are the most commonly used in the world. The work is very simple, well described and carefully tested. These pumps are robust, efficient and fairly inexpensive to manufacture. Whenever the pump is running, the fluid pressure will increase from the pump’s inlet to its outlet. The change in pressure will drive the fluid throughout the system.

This pump produces an enhanced force by transferring the mechanical power of the motor to the fluid throughout the rotating impeller. The fluid flow will enter the center of the impeller and flow out with its vanes. Centrifugal force thus increases the velocity of the fluid and energy like kinetic energy can be changed into force.

Depending on the type of water flow they produce, centrifugal pumps can be divided into three subtypes. The flow pattern is determined by the impeller shape and the pump construction.

| SUB-TYPE | DESCRIPTION | PERFORMANCE |

| Axial Flow Pump | Also known as a propeller pump, it produces water flow along the impeller shaft direction. | High flow rate Low pressure |

| Radial Flow Pump | This pump type produces flow in a direction perpendicular to the shaft (90° angle). | Low flow rate High pressure |

| Mixed Flow Pump | This pump type combines radial and axial flow, producing a conical flow pattern around the shaft. | Medium flow rate Medium pressure |

Vertical Centrifugal Pumps

Vertical centrifugal pumps are also known as cantilever pumps. These pumps use a unique shaft and maintenance design that allows the volume to fall into the pit because the bearings are on the outside of the pit. This pump model does not use a filled container to cover the shaft, but uses a throttle bushing in its place. Parts washers are a common application for this type of pump.

Horizontal centrifugal pumps

These types of pumps include at least two otherwise more impellers. These pumps are used for pumping services. Each stage is basically a manifold pump.

All phases are in a similar bunker and mounted on a similar shaft. At least eight additional phases can be installed on separate horizontal shafts. Each phase enhances the head by approximately equal amounts. A multi-stage pump can also be a single-stage pump, or else a double suction pump on the first impeller. Various pumps have been supplied and repaired for this type of centrifugal pump.

Submersible Pumps

These pumps are also known as stormwater, sewage and septic pumps. Applications for these pumps include primarily building services, domestic, industrial, commercial, rural, municipal and stormwater recycling applications.

These pumps are suitable for transferring stormwater, groundwater, sewage, blackwater, greywater, rainwater, trade waste, chemicals, bore water and food. These plumbing applications mainly include different impellers such as closed type pumps, convection pumps, vortex pumps, multistage pumps, single channel pumps, cutting pumps or grinder pumps. For different applications, a wide range of options are available, including high flow, low flow, low head or high head.

Fire hydrant system

Fire hydrant pump systems are also known as fire hydrant booster, fire pump and fire pump. These are high pressure pumps designed to increase the firefighting capacity of a building by increasing the force within the hydrant service, as the mains are not sufficient. Applications for this system include mainly irrigation and water distribution.

Positive displacement pumps

There are different types of volumetric pumps, some of which will be discussed below, such as diaphragm pumps, gear pumps, peristaltic pumps, lobe pumps, and piston pumps.

Diaphragm Pumps

Diaphragm pumps are also known as AOD pumps (Air Operated Diaphragm), pneumatic and AODD pumps. Applications for these pumps include mainly in continuous applications such as general plant, industrial and mining. AOD pumps are particularly suitable where power is not available and are otherwise used in unstable and combustible areas. These pumps are also used for transferring chemicals, industrial wastewater, food manufacturing, underground coal mines, etc.

These pumps are response pumps that include two diaphragms driven by condensing air. The air portion of the transfer valve alternately applies air to both diaphragms; each diaphragm contains a set of ball valves or check valves.

Working principle of pneumatic diaphragm pump

More detailed air operated diaphragm pump working principle and related knowledge please see this article: AODD Pumps Working Principle.

Gear Pumps

These pumps are a rotating positive displacement pump, which means they produce a steady amount of fluid with each revolution. These pumps move the fluid by entering machinery inside and outside the network for a non-exciting pumping action. These pumps are capable of pumping at high forces and can efficiently pump highly concentrated fluids.

Gear pumps do not contain any valves that cause losses such as friction and high impeller speeds. Therefore, the pumps are suitable for handling thick fluids such as fuels and grease. These pumps are not suitable for driving solids and harsh liquids.

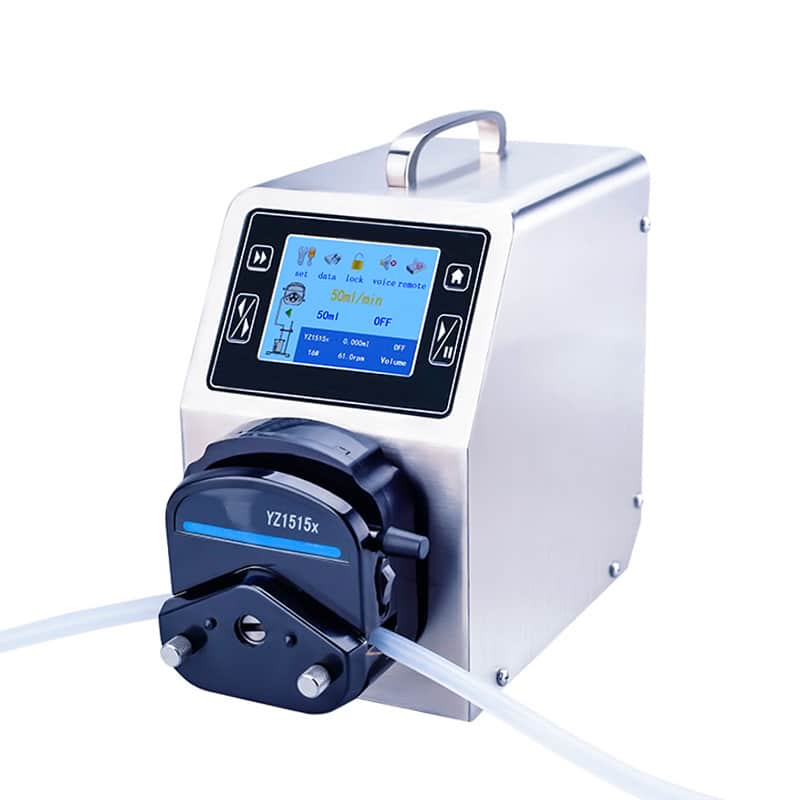

Peristaltic pumps

Peristaltic pumps are also known as tube pumps and peristaltic dosing pumps. It is a volumetric pump and the applications of these pumps are mainly related to processing in the chemical, food and water treatment industries. It provides a steady flow for measuring and mixing and is also capable of pumping various liquids such as toothpaste and various chemicals.

Lobe Pumps

Lobe pumps are also called rotor pumps and these pumps have different characteristics such as excellent efficiency, rust resistance, sanitary quality, reliability etc. These pumps can handle highly concentrated fluids and solids without harming them. These pumps may work with gear pumps, except for the vanes that do not touch each other. In addition, these pumps have superior pumping chamber compared to gear pumps that allow them to move slurry. These are made of stainless steel and are very polished.

Piston Pumps

Piston pump is a positive displacement pump, also known as a plunger pump, in which a high pressure seal responds through a piston. These pumps are often used for water irrigation, scenarios requiring high, reliable pressure and delivery systems for conveying chocolate, pastry, paint, etc.