What are dosing pumps?

Dosing pump is also called metering pump, quantitative pump or proportional pump. Metering pump is a kind of can meet the needs of all kinds of strict process flow, flow can be in the range of 0-100% stepless adjustment, used to transport liquids (especially corrosive liquids) a special volume pump.

Dosing pump is a kind of fluid conveying machinery, its outstanding feature is that it can maintain a constant flow that has nothing to do with discharge pressure. The metering pump can be used to complete the functions of conveying, measuring and regulating at the same time, thus simplifying the production process. The use of multiple metering pumps, can be several media according to the precise proportion of the input process for mixing. Because of its own outstanding, metering pump has now been widely used in petrochemical, pharmaceutical, food and other industrial fields.

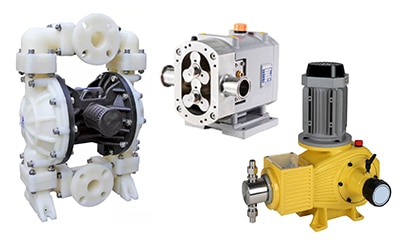

Types of dosing pumps

According to the flow part

⑴ plunger, piston type ⑵ mechanical diaphragm type ⑶ hydraulic diaphragm type

⒉ According to the driving mode

⑴ motor drive ⑵ electromagnetic drive

3. according to the way of work

⑴ Reciprocating ⑵ Rotary ⑶ Gear type

4, according to the pump characteristics

⑴ large frame ⑶ large frame ⑶ small frame ⑸ computer stand

Other classifications: electronic control, air control, heat preservation, heating, high viscosity, etc

The principle characteristics

The structure of the pump

The pump is composed of three parts: motor, transmission box and cylinder block.

The transmission box is composed of a turbine worm mechanism, a stroke adjusting mechanism and a crank connecting rod mechanism. By rotating the adjusting hand wheel to implement high adjustment stroke, so as to change the eccentricity of the moving shaft to achieve the purpose of changing the plunger (piston) stroke.

The cylinder body is composed of pump head, suction valve group, discharge valve group, plunger and packing seals.

The working principle of

The motor drives the worm through the coupling and decelerates the worm gear so that the spindle and the eccentric wheel are rotated, and the eccentric wheel drives the sliding adjusting seat of the bow connecting rod for reciprocating motion. When the plunger moves back to the dead point, a vacuum gradually forms in the pump chamber, the suction valve is opened, and the liquid is inhaled; As the plunger moves forward to the dead point, the suction valve closes, the discharge valve opens, and the fluid is expelled as the plunger moves further. The reciprocating circulation of the pump works to form a continuous pressure, quantitative discharge of liquid.

Flow control

The flow of the pump is adjusted by rotating the hand wheel, driving the adjustment screw rotation, so as to change the distance between the bow type connecting rod, change the plunger (piston) in the pump chamber travel to determine the size of the flow. Adjusting the scale of the handwheel determines the plunger stroke with 95% accuracy.

The characteristics of the pump

- The pump has superior performance, among which the diaphragm metering pump does not leak, high safety performance, accurate metering and transportation, the flow can be adjusted from zero to the maximum value range can be arbitrarily, the pressure can be arbitrarily selected from the normal pressure to the allowable range.

The regulation is intuitive and clear, the work is smooth, no noise, small volume, light weight, easy maintenance, and can be used in parallel.

The pump has a wide variety of applications, complete performance, suitable for delivery from -30 degrees to 450 degrees, viscosity of 0-800mm/s, discharge pressure up to 64MPa, flow range of 0.1-2000L /h, metering accuracy within ±1%.

According to the technical requirements, the pump can be manually adjusted and frequency conversion to adjust the flow rate, and can also realize remote control and computer automatic control.

The characteristics of

Measuring range: 0-400 L/h

Pressure range: 0-1.0 MPa

Drive mode: motor drive

Control mode: manual, automatic control (can receive 4-20mA signal to adjust the flow)

- Cast aluminum shell, high heat dissipation performance, light weight, applicable to all kinds of acid and alkali liquid, tasteless.

- the use of CAM mechanism. It is generally safe and leak-free, and can be installed on the charge tank or pipeline.

- contact medium pump head for PVC, optional PTFE, and stainless steel material.

- cost-effective, generally suitable for water treatment industry with low pressure requirements.

- When the pump is running or stopped, the flow rate can be adjusted arbitrarily, and the quantitative output can also be achieved.

- The diaphragm is made of multi-layer composite structure, the layer is super toughness Teflon acid-resistant film, the layer is EPDM elastic rubber, the third layer is thickness support iron core, the fourth layer is reinforced by reinforced nylon fiber, and the fifth is fully covered with EPDM elastic rubber, which can effectively improve the service life of the diaphragm.