Types of industrial pumps

Industrial pumps are designed for harsh or heavy-duty applications. They convey a range of material

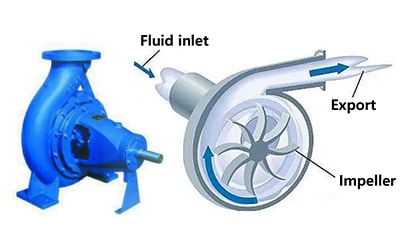

Centrifugal pump is produced by the impeller rotating centrifugal force to transport liquid pump. Before starting the pump, the pump shell and suction pipe must be filled with water, and then start the motor. The pump shaft drives the impeller and the water to do high-speed rotation, and the water will occur centrifugal movement, is thrown to the impeller outer edge, through the cochlear pump shell of the flow into the water pump pressure pipe road.

Centrifugal pump is mainly composed of impeller, shaft, shell shaft seal and seal ring. Normally, before the centrifugal pump starts, the pump shell should be filled with liquid. When the prime mover drives the pump shaft and the impeller to rotate, on the one hand, the liquid moves circumferentially with the impeller, on the other hand, under the action of centrifugal force, the liquid is thrown from the center of the impeller to the periphery. The liquid obtains pressure and velocity energy from the impeller. When the liquid flows through the volute into the discharge, part of the velocity energy will be converted to static pressure energy. When the liquid is ejected from the impeller, the central part of the impeller forms a low-pressure area, which forms a pressure difference with the pressure of the suction liquid surface, and constantly inhales and discharges the liquid under a certain pressure.

(1) Unscrew the bolts on the spout side bearing gland and the connecting nut between the spout section, the packing box, and the bearing body, and remove the bearing parts.

(2) unscrew the round nut on the shaft, remove the bearing inner ring, bearing gland and baffle in turn, remove the packing body.

(3) remove the O-ring, sleeve, balance plate and key on the shaft in turn, remove the spit section, including the final guide vane and balance ring.

(4) After removing the last stage impeller and keys, disassemble the interruption. Follow the same method to remove the other impeller, middle and guide vane, until the lower impeller is removed.

(5) Remove the connecting nut of the suction section and the bearing body, as well as the bolts on the bearing gland, and remove the bearing parts.

(6) Pull out the shaft from the suction section, unscrew the fixed nut on the shaft, and remove the bearing inner ring, O-ring, shaft sleeve and baffle sleeve in turn.

(7) When removing the self-priming centrifugal pump impeller, the axial channeling momentum and radial runout of the rotor need to be measured, and the measurement needs to be recorded in time. When the rotor rotates once, the larger value to the smaller value of the point on the same side is the runout of the point.

(8) Remove the back cap of the impeller, remove the impeller, before disassembly, carefully confirm the back cap steering, reverse force is strictly prohibited to damage the back cap. When the impeller is pried with a crowbar, it should be pried at the impeller’s rib plate to avoid cracking the impeller. Appearance check impeller back cap, there should be no bite and sliding wire phenomenon, if there should be timely repair and replacement.

(9) Remove the impeller guide flat key, check the appearance of the flat key should not be obvious deformation and missing, and the keyway should meet the requirements, if not, should repair or replace the impeller.

Industrial pumps are designed for harsh or heavy-duty applications. They convey a range of material

Mechanical seals are a key component in centrifugal pump systems. These devices maintain the integrity

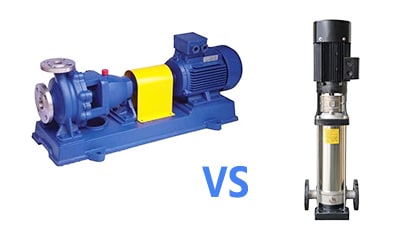

What is a centrifugal pump? A centrifugal pump is a mechanical device that moves fluid

Pump is a mechanical device used to transfer different fluids from one position to another.

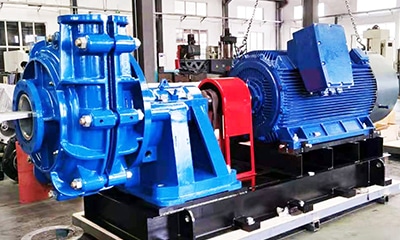

Slurry is one of the most challenging fluids to work with. It is highly abrasive,

Centrifugal pumps can be found in many industrial applications. They offer excellent operating efficiency and

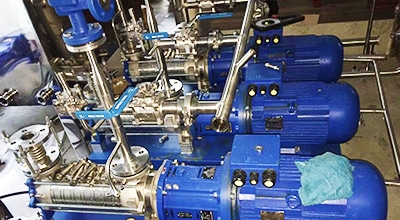

What is a screw pump? Screw pump is a part of the dry compressed gas

What is a dosing pump? Dosing pump, also known as dose pump, metering pump, is

‘HAOSH‘ is a major dosing metering pump brand of Shanghai GL Environmental Technology Co., Ltd. Also as a pump category super market, we supply diaphragm pumps, chemical pumps, water pumps, screw pumps, etc. Since founded in 2007, HAOSH brand has for more than 100 countries of the world’s more than 3000 clients with high quality pumps.