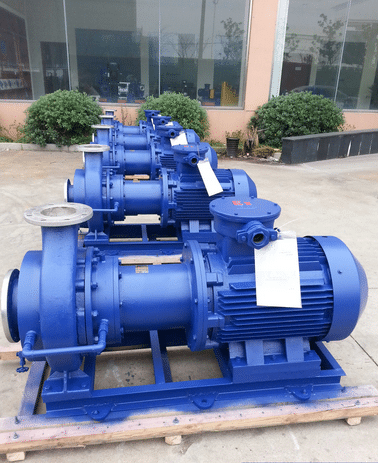

Industrial pumps are designed for harsh or heavy-duty applications. They convey a range of material types, including water and wastewater, chemicals, petroleum, oil, sludge and slurry, and food.

HAOSH PUMP has the right selection of industrial pumps as well as commercial and municipal pumps to fit your needs. We handle all types of applications – from water to aggressive chemicals, and everything in between. Our sales engineers can assist you with your selection and help ensure that your pump is operating at peak efficiency, no matter what your application is.

Industrial pumps, commercial and municipal

- End suction

- ANSI

- Non-metallic (lined and sealed)

- Magnetic drive

- Sewage pumps

- Axial flow

- Vertical turbines

- Vane

- Pulp and Paper Processes

- API Processes

- Double suction

- Multi-stage

- Rotary Gear

- Centrifugal

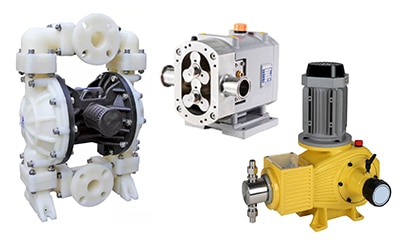

- Pneumatic piston

- Abrasive slurry handling

- Sanitary

- Self-priming

- Air operated double diaphragm (AODD)

Pumps are a key component of the way the world works today. Industrial pumps are part of most manufacturing processes. Commercial pumps keep office buildings open for business. Municipal pumps provide fresh water to our cities and remove wastewater from our cities.

Choosing the most appropriate pump for your application can ensure that it handles the task with the least amount of breakage, downtime or fluid contamination. There are many types of pumps on the market, each with its own strengths and weaknesses. Failure to select the right pump for a given use case can result in, at best, operational inefficiencies and, at worst, catastrophic equipment failure.

Markets/applications served

Each of our pumps is designed and manufactured to meet the specific needs of industrial and commercial systems. Depending on the type of pump, common applications may include:

- Water movement

- Chemical processing

- High volume fluid management

- Pressurized water/fluid

We serve a variety of applications in a wide range of industries, such as

- Agriculture. Pumps used in the agricultural sector are used to hydrate animals, facilitate irrigation, move mud, pressure wash animal casings, and more.

- Construction. Construction operations rely on a variety of pumps to mitigate flood risk, maintain construction sites and provide pressurized water for cleaning.

- Engines. Gas engines rely on internal pumps to move fuel for combustion.

- Fire suppression. Pumps are critical to maintaining pressurized water in emergency fire suppression systems. Fire engines also use pumps to pump water from the municipal system through fire hydrants.

- Flood control. Industrial sump pumps and other submersible pumps are critical to preventing flooding in industrial and commercial buildings.

- Industrial. Pumps are used in a wide range of industrial applications, such as moving process chemicals, supporting manufacturing processes, feeding boilers, pressurization, filtration and many other tasks.

- Municipal. Complex municipal water systems rely heavily on equally complex pump systems to maintain water pressure throughout the water supply network.

- Sewage and waste. Pumps facilitate the movement of a wide variety of liquid and solid wastes.

Industrial Pump Selection Considerations

Choosing the right pump for a commercial or industrial application is critical to the lifetime performance of your system – but sometimes it can be a complex choice. Each pump comes in dozens of different sizes, and there are dozens of considerations for each application. When looking for the right pump, keep these four considerations in mind.

- Material of construction

Choose a pump based on the material’s ability to withstand the fluid composition and chemicals in the surrounding environment. Common materials include bronze, cast iron and stainless steel. Different applications may also require pumps that meet strict regulatory standards. - Fluid properties

Corrosive fluids, process fluids containing solids and heating fluids all require different material handling and pump construction. Pay careful attention to process fluid properties that may reduce pump performance or put pressure on the pump to ensure selection of the appropriate model. - Power requirements and availability

High horsepower pumps that must tightly control process fluid pressure require the use of an appropriate and reliable power supply. Many pumps are available in electric and pneumatic types for installation environments and mobile applications, such as agriculture and construction sites. In addition to considering the power supply, the appropriate pump must be selected based on any voltage or current limitations. - Flow requirements

Different pump mechanisms control the pressure of the process fluid. Friction, height and kinetic energy build-up can change the pressure level of the fluid to meet the needs of the application. It is important to select the right pump based on its pressurization mechanism, the expected height or submersion of the pump and its intended application.

Industrial pump types and examples

- End suction pumps – The pumped liquid increases in speed as it moves along the impeller’s vanes. The liquid then enters the worm housing where the diffusion process converts the high velocity into high pressure.

- ANSI pump – the only pump in the United States that is recognized as a dimensional standard by the American National Standards Institute.

- Non-metallic (lined and sealed) pumps – corrosion and wear resistant to withstand a variety of severe service applications.

- Magnetic Drive Pumps – Their main feature is that the motor’s shaft does not extend into the internal pump, thus eliminating the need for a shaft seal to prevent any leakage and thus reducing maintenance costs.

- Sump Pumps – are typically installed in a sump pit where water flows through a drain or through the natural migration of the soil.

- Axial flow pumps – consist of an axial impeller in a pipe that can be driven directly by a sealed motor.

- Vertical turbine pumps – designed to pump water from wells deep underground.

- Vane pumps – best suited to handle low viscosity liquids. No internal metal-to-metal contact.

- Pulp and Paper Process Pumps – Perfect for the pulp and paper industry, known for its tough abrasive processes.

- API Process Pumps– Meets American Petroleum Institute standards for pumps handling hydrocarbons.

- Split Pumps– Housing is divided into two separate chambers for lower cost for high flow applications. Impellers can be supported by bearings on both sides.

- Double suction pumps – receive suction liquid on both sides of the impeller, balancing the impeller thrust.

- Multi-stage pumps – use multiple impellers that can be mounted on the same or different shafts.

- Rotary gear pumps – the meshing of gears pumps fluid through displacement.

- Centrifugal pumps – use impellers to move water and many other fluids.

- Pneumatic piston pumps – use high pressure air to power or move a piston

- Abrasive slurry handling pumps – capable of handling large quantities of abrasive solids and mixtures.

- Sanitary pumps – used to transport food and agriculture in operations that require cleanliness.

- Self-priming pumps– a centrifugal pump that uses a mixture of air and water.

- Air Operated Double Diaphragm (AODD) – Uses compressed air as the power source.