What is a screw pump?

Screw pump is a part of the dry compressed gas transfer pump series. They are positive displacement pumps that use one or more screws to move fluid or water along the screw shaft. These screws interlock to pressurize the fluid and move it into the system. These screws engage each other and reciprocate in the cavity of the cylinder. They are often used in industrial vacuum applications, often in combination with Roots blowers, and as oil-free roughing pumps in high vacuum and ultra-high vacuum systems. Please check out the description of various pumps

How does a screw pump work?

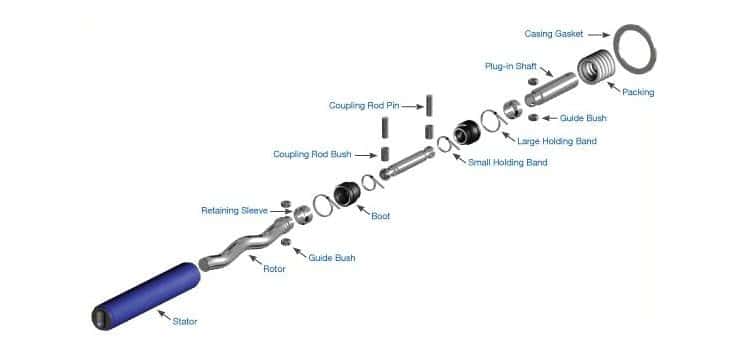

Screw pump operates with two counter-rotating screw rotors that are carefully designed to rotate “toward each other”. This traps the gas in the space between the rotor “screws”. As the screws rotate, this trapped volume is reduced, which not only compresses the gas, but also moves it toward the exhaust port.

When the progressive cavity pump begins to operate, power is supplied to the drive screw via an electric motor. The drive shaft is connected to the screwdriver that drives the screwdriver.

When the drive screw starts to rotate, the driven screws also rotate, as these screws engage each other. Due to the movement of these screws, a minimum vacuum starts to be generated in the inlet section. Due to this vacuum, fluid is drawn into the pump through the inlet valve.

As the fluid enters the pump, it becomes trapped between the gaps in the “screws”. This trapped fluid also moves with the rotation of the screw. As the screw moves, the volume of the trapped fluid decreases and the pressure of the fluid increases.

As the pressure of the fluid increases according to the desired pressure, it is discharged from the outlet valve and moved to the desired location.

When a screw pump pumps oil or other types of viscous fluids, the screw surfaces are lubricated as the fluid is pumped, so there is little or no clearance between the screws.

However, when pumping gas/water mixtures, water, or other types of light liquids, these components cannot come into contact with each other. If there is no contact, the parts will wear out quickly. Therefore, do not use a triple screw pump (where one screw drives the other two without gears) for water supply or multi-phase operation.

To better understand how it works, please watch the following video:

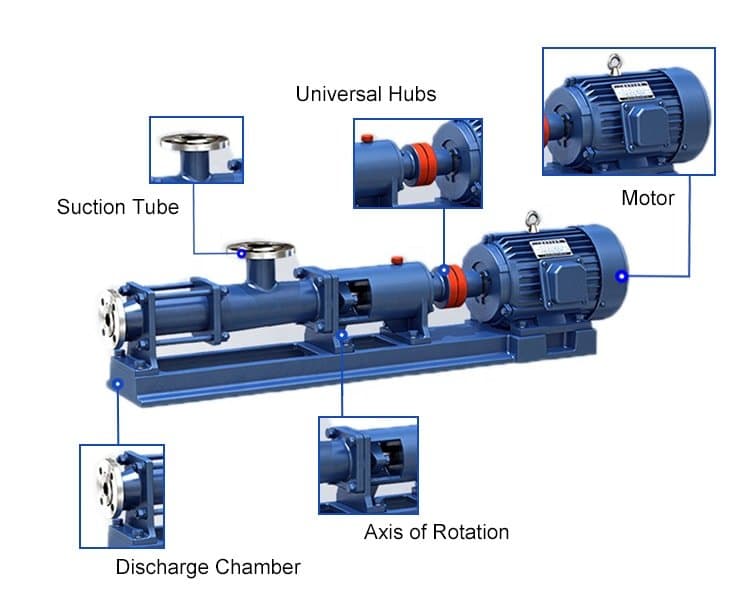

Composition of the screw pump

- Screwdriver

- Slave screw

- Timing gear

- Inlet and outlet

- Pressure relief valve

- Bearings

- Drive shaft

Characteristics of screw pump

Advantages

- These pumps are easy to maintain.

- Progressive cavity pumps can be used for all fluids

- It can be dried up

- It has a compact structure

- These pumps provide constant and non-pulsating fluid flow

- These have a quiet operation

- The pump can produce greater volumetric efficiency

- High reliability

- Self-priming capability

- High robustness

- The progressive cavity pump does not pump contaminants in the fluid

- It has frictionless rotation

- With a progressive cavity pump, you can also pump high viscosity fluids without losing flow

- High resistance to water vapor and particles/dust

- Very high pumping speed

- No contamination of the pumped medium

- Frictionless rotation – eliminates rotor wear

- High efficiency due to internal compression

- Relatively low operating costs and maintenance requirements

- Inverter operation – easily optimized for process requirements – resulting in high energy efficiency

Disadvantages

- Installation costs for small industries are high.

- The pump requires gas ballast to transfer light gases quality

- Without gas ballast, the ultimate pressure and pumping speed of light gases (helium and hydrogen) are reduced

- cannot be scaled down to small pumping speeds below 50 m³/h; below approx. 100 m³/h multi-stage Roots or scroll pumps are used

Application of screw pumps

Screw pumps have become the standard solution for almost all industrial vacuum processes. Vacuum furnaces for brazing or sintering, metallurgical systems, and even steel degassing equipment have the advantage of dustproofing and long service intervals. In food processing, food drying, food packaging and even freeze dryers tend to use oil-free progressive cavity pumps to avoid contamination of the pump oil with water or process debris. Large-scale coating like architectural glass coating machine use screw pump as a high vacuum pump rough pumping. Screw pumps are also ideal for regeneration of large cryogenic pumps.

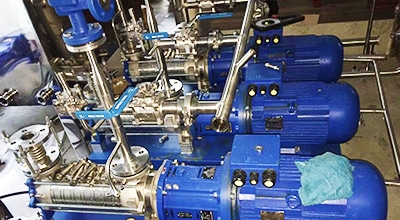

Many lubrication and hydraulic machines use screw pumps to supply oil for large machines.

Screw pumps are more helpful in pumping heavy oil. They even have the ability to pump higher flow rates and higher viscosity fluids.

These pumps are capable of pumping both liquids and gases. For this reason, these pumps are used in many pumping industries.

The pumps are also used in oil and gas, mining and manufacturing industries.

These pumps are used in the ceramic, chemical, paint, food and paper industries.